Background Overview

In the field of industrial washing machines, equipment needs to operate in various harsh working environments, including high humidity and high temperatures. The operating characteristics of industrial washing machines require inverters to have specific functions to ensure stable operation and efficient performance.

Load Characteristics

During the washing process, the running frequency is around 10Hz.

Heavy load at low frequency.

Frequent switching between forward and reverse running.

Occurrence of large surge currents.

During the spinning-drying process, the running frequency is as high as 130Hz or higher.

The working environment is usually high humidity and high temperature.

Requirements for the Inverter

Soft start of the motor to reduce surge current.

Stable operation at high speed.

KD600 Inverter Solution

The KD600 series inverters meet the needs of industrial washing machines through the following features:

Multistage Speed Control:By setting multiple speeds, the KD600 inverter can achieve precise frequency control to adapt to different stages of washing and drying.

Soft Start Function: The KD600 inverter has a soft start function that effectively reduces the large surge currents when the motor starts, protecting the motor and electrical system.

High-Frequency Operational Stability: At high frequencies (e.g., 130Hz), the KD600 inverter can maintain stable operation, ensuring efficient operation during the drying stage.

Environmental Adaptability: The KD600 inverter can operate stably in high humidity and high temperature environments, ensuring long-term reliability of the equipment.

Parameter Setting Steps

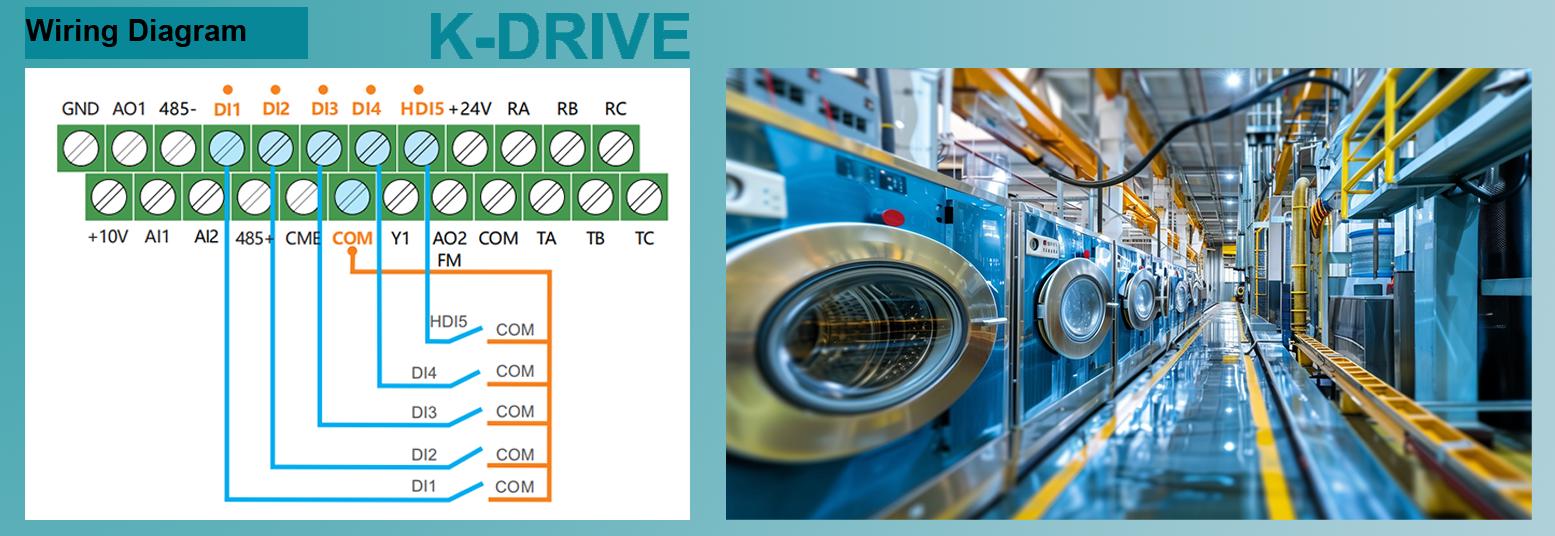

To achieve optimal performance in industrial washing machines, the KD600 inverter's parameters are set as follows:

P0-04 Set to 1: Terminal control start and stop.

P0-06 Set to 4: Multistage speed command.

P5-00 Set to 1: Forward running.

P5-01 Set to 12: Multistage speed 1.

P5-02 Set to 13: Multistage speed 2.

P5-03 Set to 14: Multistage speed 3.

P5-04 Set to 15: Multistage speed 4.

PC-01 Set as needed: Multistage speed 1 frequency percentage.

PC-02 Set as needed:Multistage speed 2 frequency percentage.

PC-04 Set as needed: Multistage speed 3 frequency percentage.

PC-08 Set as needed: Multistage speed 4 frequency percentage.

Application Effects

By using the KD600 series inverters, industrial washing machines perform excellently under various conditions, operating smoothly and reliably, significantly improving work efficiency and equipment lifespan. User feedback shows that the KD600 inverter is effective in reducing surge currents and enhancing high-frequency stability.

Conclusion

With its excellent performance and reliability, the KD600 series inverters have become the ideal choice in the field of industrial washing machines, meeting the demands of equipment operating under high load and harsh environments, and effectively improving overall production efficiency.

Keywords

Industrial washing machine, inverter, KD600 series, soft start function, high-frequency stability, multistage speed control, surge current, high humidity and high temperature environment, industrial automation, equipment reliability, work efficiency, production efficiency, industrial applications, equipment lifespan

Through the above case study, we can see that the KD600 series inverters have a wide range of applications and excellent performance in the field of industrial washing machines, becoming a highlight in the field of industrial automation.

Address: Building 1#, Auto Science and Technology Park, No. 13, Huanlian Road, Changsha High-tech Development Zone, Hunan Province

Address: Building 1#, Auto Science and Technology Park, No. 13, Huanlian Road, Changsha High-tech Development Zone, Hunan Province  +86 - 19924552818 (Whatsapp)

+86 - 19924552818 (Whatsapp)