Overview

In recent years, China's economy has sustained rapid development, energy problems have become more and more to become the main elbow of the development of the industry, and with the rapid rise in energy prices, the fierce competition in the domestic market, energy conservation has become the main problem facing the development of many ind-ustries, especially some energy consumption is relatively large industries such as petroleu-m, chemical, pharmaceutical, metallurgy, manufacturing, environmental protection, munici-pal and other industries. According to the data, the total capacity of high and low voltage motors in China is more than 35000MW, most of them are fan pump loads, and most of them work in high energy consumption and low efficiency.

General fan, pump system most of the valve to adjust the water flow or pressure, baffle this regulation is to increase the loss of the pipe network, consume a lot of energy at the cost, therefore, inevitably cause the waste of electric energy. And because the design, the system is designed according to the maximum load, in the actual operation, most of the time the system is impossible to run in the full load state, there is a large surplus, so there is a large energy saving potential.

Using KD600 frequency conversion speed control device, by changing the speed of the fan, so as to change the fan air volume to meet the needs of the production process, and the operation energy consumption is the most saving, the highest comprehensive benefit. Therefore, variable frequency speed regulation is an efficient and optimal speed regulation scheme, which can realize the stepless speed regulation of the fan, and can conveniently form a closed-loop control system to achieve constant pressure or constant flow control.

Frequency conversion speed regulation energy-saving principle

According to the principle of fluid mechanics, the relationship between shaft power P and air volume Q and wind pressure H of the fan driven by induction motor is as follows:

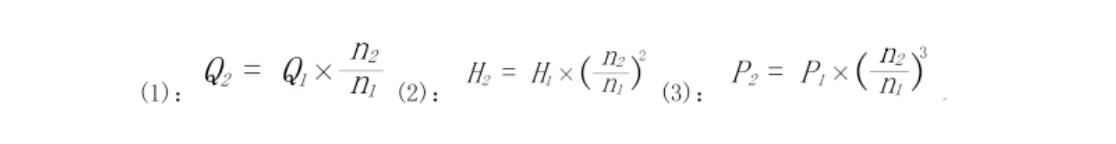

“Q*H When the speed of the motor changes from n1 to n2, the relationship between Q, H, P and the speed is as follows:

It can be seen that the air volume Q is proportional to the speed n of the motor, and the required shaft power P is proportional to the cube of the speed. Therefore, when 80% of the rated air volume is required, by adjusting the speed of the motor to 80% of the rated speed, that is, adjusting the frequency to 40.00Hz, the required power will only be 51.2% of the original.

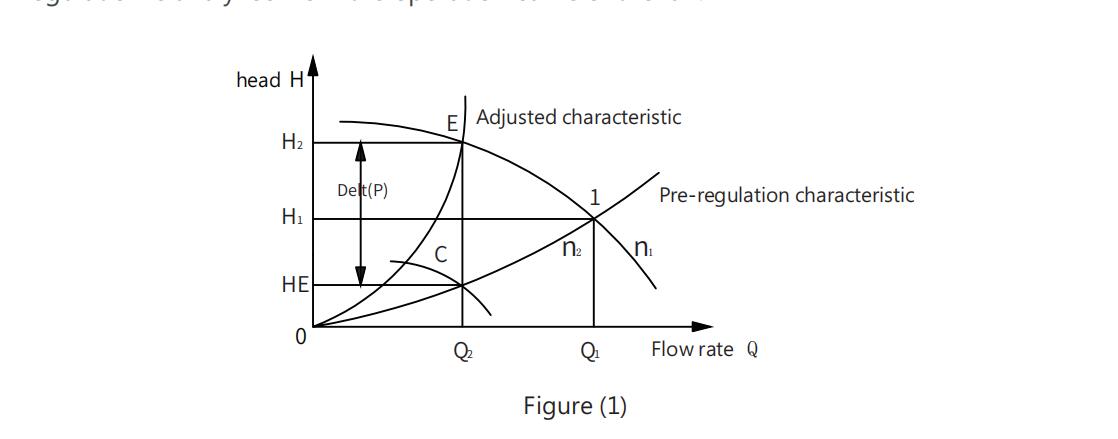

As shown in Figure (1), the energy saving effect after adopting variable frequency speed regulation is analyzed from the operation curve of the fan.

When the required air volume decreases from Q1 to Q2, if the method of adjusting the damper is adopted, the pipe network resistance will increase, the pipe network charact-eristic curve will move up, the operating condition point of the system will change from point A to the new operating condition point B, and the required shaft power P2 is pro-portionalto the area H2×Q2. If the speed control mode is adopted, the fan speed drops from n1 to n2, the network characteristics do not change, but the fan characteristic curve will move down, so its operating condition point is moved from A to C. At this time, the required shaft power P3 is proportional to the area HB×Q2. Theoretically, the shaft power Delt(P) saved is proportional to the area of (H2-HB) × (C-B).

Considering the reduction of efficiency after deceleration and the additional loss of speed regulating device, through practical statistics, fans can save energy by speed regulating control up to 20% ~ 50%.

Variable frequency speed control advantage

The power factor of the network side is improved: when the original motor is directly driven by the power frequency, the power factor is about 0.85 at full load, and the ac-tual running power factor is much lower than 0.8. After adopting the frequency conve-rsion speed regulation system, the power factor of the power side can be increased to more than 0.9, and the reactive power can be greatly reduced without the reactive power compensation device, which can meet the requirements of the power grid and further save the operating costs of upstream equipment.

Equipment operation and maintenance costs decreased: After the use of frequency co- nversion adjustment, due to the adjustment of motor speed to achieve energy saving, when the load rate is low, the motor speed is also reduced, the main equipment and corresponding auxiliary equipment such as bearings wear less than before, the maint- enance cycle can be extended, equipment operating life is extended; And after the conversion transformation, the opening of the damper can reach 100%, and the operationis not under pressure, which can significantly reduce the maintenance of the damper. In the operation of the frequency converter, only need to regularly dust the frequency converter, without stopping, to ensure the continuity of production. With the needs of production, adjust the speed of the fan, and then adjust the air volume of the fan, which not only meets the requirements of the production process, but also greatly reduces the work intensity. After adopting frequency conversion technology for speed regulation, mechanical wear is reduced, maintenance workload is reduced, and maintenance costs are reduced.

After the frequency conversion speed regulating device is used, the motor can be soft- started, and the current does not exceed 1.2 times the rated current of the motor when starting, without any impact on the power grid, and the service life of the motor is extended. In the entire operating range, the motor can ensure smooth operation, reduce losses, and normal temperature rise. The noise and starting current of the fan are very small when starting, without any abnormal vibration and noise.

Compared with the original old system, the inverter has a number of protection functions such as overcurrent, short circuit, overvoltage, undervoltage, lack of phase, temperature rise, etc., to better protect the motor.

Simpleoperation and convenient operation. Parameters such as air volume or pressure can be set remotely by computer to achieve intelligent regulation.

Theability to adapt to power grid voltage fluctuations is strong, the voltage working range is wide, and the system can operate normally when the power grid voltage fluctuates between -15% and +10%.

Application site

Address: Building 1#, Auto Science and Technology Park, No. 13, Huanlian Road, Changsha High-tech Development Zone, Hunan Province

Address: Building 1#, Auto Science and Technology Park, No. 13, Huanlian Road, Changsha High-tech Development Zone, Hunan Province  +86 - 19924552818 (Whatsapp)

+86 - 19924552818 (Whatsapp)