The constant pressure water supply system utilizes Variable Frequency Drives (VFDs) to control the operating frequency of water pumps, ensuring a stable water pressure supply. Below is a detailed introduction to the practical application of the constant pressure water supply system based on the KD600 series inverters:

System Features

PID Function:The constant pressure water supply system requires the use of PID control to ensure system stability and precise pressure control.

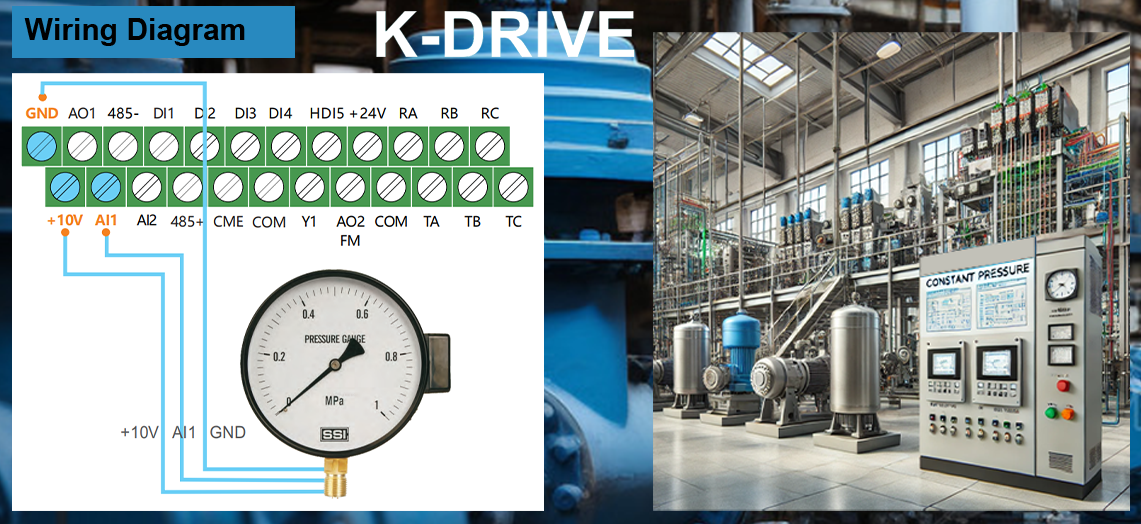

Pressure Sensor: A pressure sensor must be installed in the system to monitor the water pressure in real-time and send feedback signals to the inverter for adjustment.

Energy Efficiency Calculation

In a constant pressure water supply system, the improvement in energy efficiency mainly depends on the operating frequency of the inverter. For example, when the operating frequency is H1, the energy-saving effect can be calculated using the following formula:

Energy Saving = 1 - (H1/50)^3

Inverter Requirements

Soft Start for Motor: The soft start function of the inverter can reduce surge current during startup, protecting the motor and the system.

Stable PID Control: The inverter should provide stable PID control to ensure constant water pressure.

Precautions

Selecting the Appropriate Pressure Sensor: Ensure that the pressure sensor's range is suitable for the system's requirements. For example, if the pressure sensor's measurement range is 16 bar (1.6 MPa) and the target pressure is 5 bar (0.5 MPa), the calculation for P6-04 is as follows:

P6-04 = (5/16) * 100% = 31.3%

Parameter Setting Steps

Set P0-04 to 1: Control start and stop via terminal.

Set P0-06 to 6: Set value according to the specific need.

Set PA-01: Set PID given value as needed.

Set PA-03 to 0: PID feedback value is set by analog input AI1.

Set B6-00 to 2: Select hibernate mode.

Set B6-01: Set sleep frequency as needed.

Set B6-03: Set wake-up difference as needed.

Application Example

Shenzhen K-easy Automation Co., Ltd. has successfully implemented an efficient and stable constant pressure water supply system using KD600 series inverters. This system not only improves energy efficiency but also effectively reduces motor wear and extends the equipment's service life.

Through the above configurations and settings, the KD600 series inverters can deliver excellent control performance in constant pressure water supply systems, ensuring stable water pressure and high operational efficiency.

Address: Building 1#, Auto Science and Technology Park, No. 13, Huanlian Road, Changsha High-tech Development Zone, Hunan Province

Address: Building 1#, Auto Science and Technology Park, No. 13, Huanlian Road, Changsha High-tech Development Zone, Hunan Province  +86 - 19924552818 (Whatsapp)

+86 - 19924552818 (Whatsapp)